Table Blasters

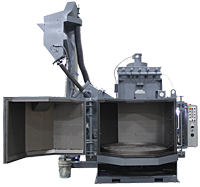

(11)Gibson Table Blasters

- Versatile, rugged systems that deliver consistent, repeatable results

- Easy to install, simple to operate

Gibson Table Blasters process parts weighing up to 10,000 pounds with diameters up to eight feet and heights exceeding four. Featuring eleven standard models, Gibson’s line of Table Blasters provides the versatility and flexibility to efficiently blast parts ranging from ten-pound gears to heavy fabrications.

These rugged machines facilitate cleaning, peening, deburring, profiling, finishing and many other surface conditioning tasks in metal-intensive industries involving casting, welding and fabrication.

For processing, parts are loaded onto a powered turntable which rotates within the blast envelope to provide 360º exposure to the blast stream. Models with an oscillating blast wheel, such as our 36" Power Table, enhance blast coverage. Features like the swing door on our Table Blasters expedite loading and unloading by enabling the operator to swing the system’s door-mounted turntable in and out of the blast enclosure.

All models feature abrasion-resistant liners on turntables for extended service life. Models used with heavy parts are designed for overhead loading and unloading with either a hoist or crane.

Hanger Blast Systems

(4)Gibson spinner hanger blasting systems provide a cost-effective solution to batch cleaning. They are designed and built for ease of use and efficiency.

/Asset/GIBSON 60X84 HANGER BLAST.png

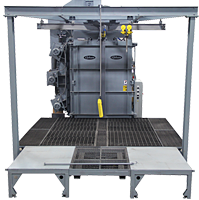

Dual Chamber Spinner Hangers

(5)Gibson Dual-Chamber Spinner Hangers

- Speed batch blasting of sensitive parts

- Deliver 360º workpiece coverage

- Continue working during loading

Gibson Spinner Hangers provide an ideal solution for batch blasting many types of parts too fragile or awkward for other methods of automated finishing. These systems play a profit-boosting role across a broad range of metal-intensive industries by improving quality and efficiency during the cleaning, peening, prepping and finishing of almost any workpiece suitable for mounting on hooks.

Our systems include two work chambers mounted on an indexing turntable. As the turntable steps through programmed positions, one chamber exposes parts to a contained blast stream emanating from high-efficiency wheels while the other opens to the operator, who loads and unloads parts from the un-contained chamber. To assure uniform coverage, a spindle rotates the hangers within the working chamber’s blast envelope.

Like all Gibson systems, our Spinner Hangers are easy to operate and install. Plus, they deliver consistent results whether working intermittently or non-stop in a multishift production facility.

PLC programming assures repeatable performance cycle after cycle, and cast liners on work-chamber walls extend equipment life. Hanger capacities from 125 to 2,000 pounds fit most applications.

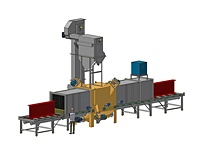

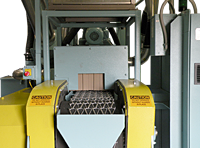

Wire Mesh Belt Blasters

Gibson Wire Mesh Belt Blasters offer the ability to utilize a blasting machine in conjunction with another machine to automate a process reducing high labor costs normally associated with batch type blasters. They come in many belt widths beginning with our 12” wide belt and are offered in larger widths. They also come with multiple blast wheels and horse powers with a level of speed and efficiency unmatched by other equipment manufactures.Gibson produces these flow through type units in many different sizes and configurations and can be customized to accommodate your blasting needs.

The operator or robot loads parts onto a manganese mesh belt while the blaster does the work, with no need for opening and closing doors. By flowing these parts within the blast envelope, these machines deliver consistent results automatically while working non-stop in a multi-shift production facility. May require an additional operator depending on how the process is organized.

These rugged machines can automate your process whether you are just cleaning or removing flash from die-cast parts this is a great option for automating and streamlining your shot blast process.

Monorail Blast System

The Gibson monorail blast system is a fully automated blast system designed for 24 hour production. Systems are typically used in applications blasting heavier parts at a high rate. Blast systems are easily integrated into the rest of the production flow such as paint lines.

Gibson monorail blast systems offer the ability to utilize a blasting machine in conjunction with another machine to automate a process reducing high labor costs normally associated with batch type blasters. They come in many different blast envelopes. They also come with multiple blast wheels and horse powers with a level of speed and efficiency unmatched by other equipment manufactures.

Gibson produces these flow through type units in many different sizes and configurations and can be customized to accommodate your blasting needs.

By flowing these parts within the blast envelope, these machines deliver consistent results automatically while working non-stop in a multi-shift production facility.

These rugged machines can automate your process whether you are just cleaning or removing flash from die-cast parts this is a great option for automating and streamlining your shot blast process.

Typical Monorail Uses:

- High Production Rates

- Large Fabrications

- Blasting of Heavier Parts or Components

- External Finishing

- Sand Removal

- Cast Parts

Key Features:

- Continuous Flow Production

- Manganese Blast Cabinet & Cast Alloy Liners

- Equipment Designed & Manufactured in the U.S.A.

- Entrance & Exit Vestibules for Abrasive Containment

- Triple Seal for Abrasive Containment from Rail

- Ease of Maintenance

- Equipment Warranty

- Multiple Blast Wheels Positioned for Optimum Coverage

Factory Options:

- Automatic Abrasive Blow Off System

- Variable Frequency Drive Blast Wheels

- High Level Media Separation

- MagnaValves for Ease of Abrasive Metering and Maintenance

- Manual Touchup Booth for Complex Part Geometries

Customization:

- Engineered Solutions for Blast Wheel Locations Ensuring Optimum Part Coverage

- Control Options and Part Recipes

Dust Collectors

- Photohelic Gauge

- Magnehelic Gauge

- HEPA Filters

- After Filters

- Silencers

- Abrasive Resistant Inlets

- Reverse Pulse

- Rotary Air Locks

- Explosion Vents